Rupture discs are the most common devices used for pressure protection. Industrial plants usually depend on them a lot. It is next to the safety valves. Rupture discs protect vessels and pipelines from deformation and

Rupture discs are the most common devices used for pressure protection. Industrial plants usually depend on them a lot. It is next to the safety valves. Rupture discs protect vessels and pipelines from deformation and other damages. A rupture disc comes in many names. This includes pressure safety disc, bursting disc, burst disc, and burst diaphragm. It is a non-reclosing pressure relief safety device.

Proper installation will ensure that the rupture disc will do its job. There are risks of safety accidents if you do not follow proper installation methods.

Preparation

Be familiar first with the preparation before you install the rupture disc. This is important to prevent any untoward incidents.

- Rupture disc inspection

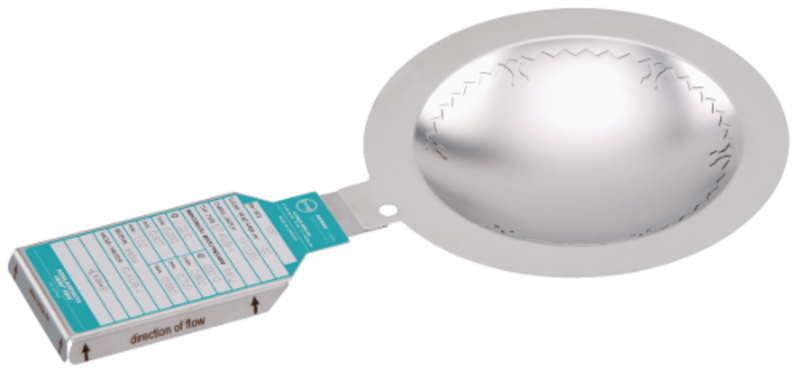

Be careful when you hold the disc and the nameplate. Check sheet at the edge of the disk. Also, check the surface of the dome. Do not install if there is any damage such as grooves, scratches, or stains. Damage disc can rupture earlier and it may not be safe.

- Holder inspection

Inspect both sides of the sheet where you will assemble the holder disc. Ensure that there are no dust or small sands. They will damage the rupture disc. Alien substances and damages affect the operation of the disc. It can also damage the disc or cause leakage. It should be clean as much as possible. The size and grade of the holder should be consistent with that of the flange. There should be no modification or process on the rupture disc and holder. Unless authorized by FDC.

Installation

If you install the rupture disc with care, then it can do its purpose. It will also lessen the possibility of accidents. Maintenance will also be easier.

- You can install a rupture disc in a vertical or horizontal method.

- The installation of a rupture disc depends on the direction of material flow.

- Be careful when handling a rupture disc. Do not touch processed parts. Use the sheet at the edge of the disk to avoid any damage to the disc.

- You should install the rupture disc together with a holder.

- Make sure that the surface of both holders where you will assemble the rupture disc is clean. It should be free from dust and damage. Tighten the bolt with symmetrical power.

ASME and other pressure vessel codes permit the use of rupture discs. It provides a wide range of benefits. Not all rupture discs are suitable for installation below safety valves. Thanks to modern disc technology, a safe and versatile installation can now be often done. Useful benefits come with it. A disc installed below a safety valve should be a non-fragmenting design. Fragments from a disc will damage the valve and/or seat. It will also result in blockage of the valve. It also damages other downstream equipment.